Source: Fraunhofer IPA/Photo: Rainer Bez

Assembly planning rethought

Cost-intensive, time-consuming and error-prone – these are obstacles in previous assembly planning. The company, which was founded at Fraunhofer IPA in 2022 “Assemblio GmbH” meets these challenges with AI-based intelligent and automated assembly planning.

In view of the increasing cost and time pressure as well as the shortage of skilled workers, adjusting screws must be found in the assembly for optimization. Conventional assembly planning requires up to 50 percent of the personnel costs and about 20 percent of the total manufacturing costs of a product.

On the one hand, this results from the time-consuming planning process, which requires many loops. On the other hand, comprehensive automated planning is often impractical for technical and economic reasons. Instead, the previous procedure is strongly based on the experience of the planners. They often proceed according to the principle of “assembly by disassembly”. An existing assembly is disassembled step by step to capture the individual steps. In the subsequent editorial process, assembly instructions are created – far away from the assembly designer. All in all, it is a complex and error-prone process.

Spin-off at Fraunhofer IPA

This is about the Fraunhofer IPA spin-off called “Assemblio”. It has set itself the goal of optimizing the inefficient aspects of assembly planning. The founding team led by Alexander Neb was supported by Fraunhofer Venture from the idea phase to the spin-off in 2022 and took part in the AHEAD technology transfer program. An intense and exciting time for Neb, in which he not only founded Assemblio, but also successfully defended his dissertation and became a father: “Life is beautiful and as long as we enjoy work, research and family we have no limits,” says Neb, describing his motivation.

Intelligent assembly thanks to AI

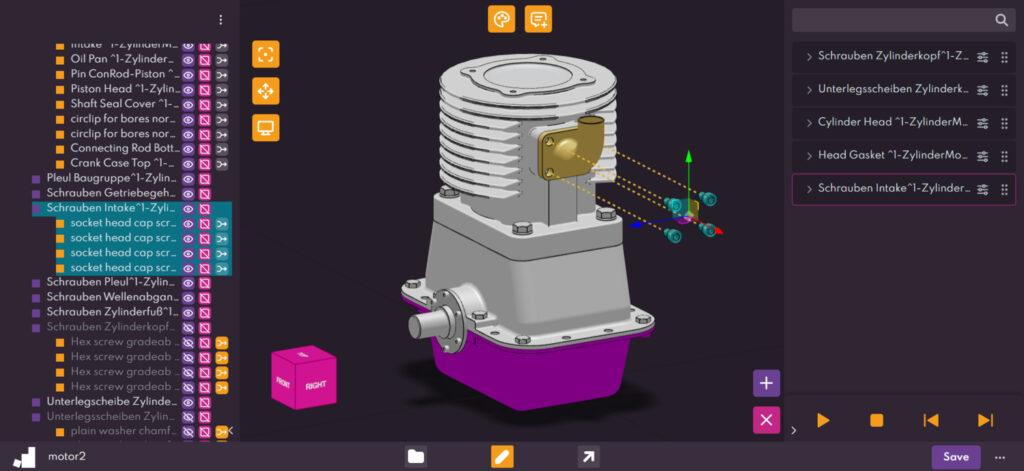

With the “Assembly Suite” software, he and his team want to improve assembly using artificial intelligence (AI) and optimize manual assembly planning. The tool consists of two components. First of all, so-called “STEP files” are analyzed and evaluated using AI. These information-rich files can be generated by any CAD system and provide the 3D analysis AI with all the information needed to accurately derive structured assembly information. This reduces the effort involved in assembly planning to a minimum and helps to avoid errors in advance.

The second component is the Assembly Composer. Here, assembly information is extracted from the 3D analysis AI and transferred to a graphical tool for assembly planning. Professionals can use this visualized assembly information to intuitively plan assembly in three dimensions. This replaces a previously manual and often unstructured process. “User studies show that our intuitive graphical operation saves 92 percent of the time required to create assembly instructions,” says Neb.

“Start-ups tend to overengineer,” he continues. Products are created with more functions or excessive scope than customers require. For this reason, it was crucial for his team to validate the development in everyday life when developing the software components. “It was only through these tests that we were able to develop a suitable product in this short time”.

Personalization instead of mass production

Due to the continuing development into a consumer-oriented market (“mass personalization”), assembly planning must become increasingly flexible. The assembly planning of the future must therefore cope with frequent changes, numerous variants and a wide variety of products.

Only in this way can the assembly planning system be flexibly adapted to the specific requirements of the customers. “At Assemblio, we believe that efficient assembly planning is critical to the future success of these companies. That is why these needs are at the heart of our development,” emphasizes Neb.

Planning for tomorrow

The Fraunhofer IPA spin-off is only at the beginning with its ideas. The next step is to tackle issues such as planning and outsourcing of the assembly stations. Numerous inquiries from the company confirm that Assemblio is on the right track and meets market requirements. Neb is helping the future founding teams at Fraunhofer IPA: “Thanks to the Fraunhofer Venture and the AHEAD program, we were able to take the right steps towards our vision. Seize the opportunities that are available to you, and always keep an eye on your vision and the fun of working.