Source: Fraunhofer IPA/Photo: Rainer Bez

Digital Helpers for Assembly Automation

An app to determine the potential for automation, and a website for automation-friendly components design: Companies can use these two tools to make assembly more efficient and economical. Both can be used with just a few clicks.

Assembly is often the area that is performed manually, in contrast to many other production steps. This is due to a large number of variants for small jobs, a wide variety of processes and process requirements, and undefined parts provision. It is often possible with the right know-how, however, to implement full or partial automation with human-robot cooperation (HRC) for assembly.

The Fraunhofer IPA has already advised many companies on five continents about these issues. Experts use specially-developed automation potential analysis (APA). Experts use APA to examine every assembly step, using the criteria of separation, handling, positioning and joining. These four criteria are then broken down even more. For example, positioning is subdivided into detailed aspects of target position tolerances, existing positioning aids, accessibility, joining movement, joining tolerances and holding stability. Each process is re-evaluated accordingly. In addition, it investigates possible time savings and ergonomic characteristics. Experience has shown that this investigation demonstrates that about a tenth of assembly processes can, in principle, be considered for automation.

Automation expert via an app

Until now, this process was tied to an expert’s knowledge. Also, data that accrues with each APA could only be managed manually, and could not be used to evaluate automation, for example. Fraunhofer IPA is now offering an app for Android devices that bundles previously personal knowledge in order to make the APA much more customer-friendly, and use the data results better. This is available digitally to all interested companies.

“Anyone can become an expert in evaluating assembly processes with our APA app,” explains Alexander Neb, a research assistant at Fraunhofer IPA, who helped develop the app. The app is currently available as Version 2.0. First users can use them with a simple license agreement. The app is not just restricted to assembly: “We are working on integrating HRC into the app, as we see many possible uses for this in assembly.” Machine assembly and dismantling are further topics being considered. “That’s because both aspects are becoming more important, due to companies’ increased environmental awareness and a changing legal environment,” explains Neb. “We look forward to inquiries from interested companies that would like to implement these developments with us.”

Have components evaluated automatically

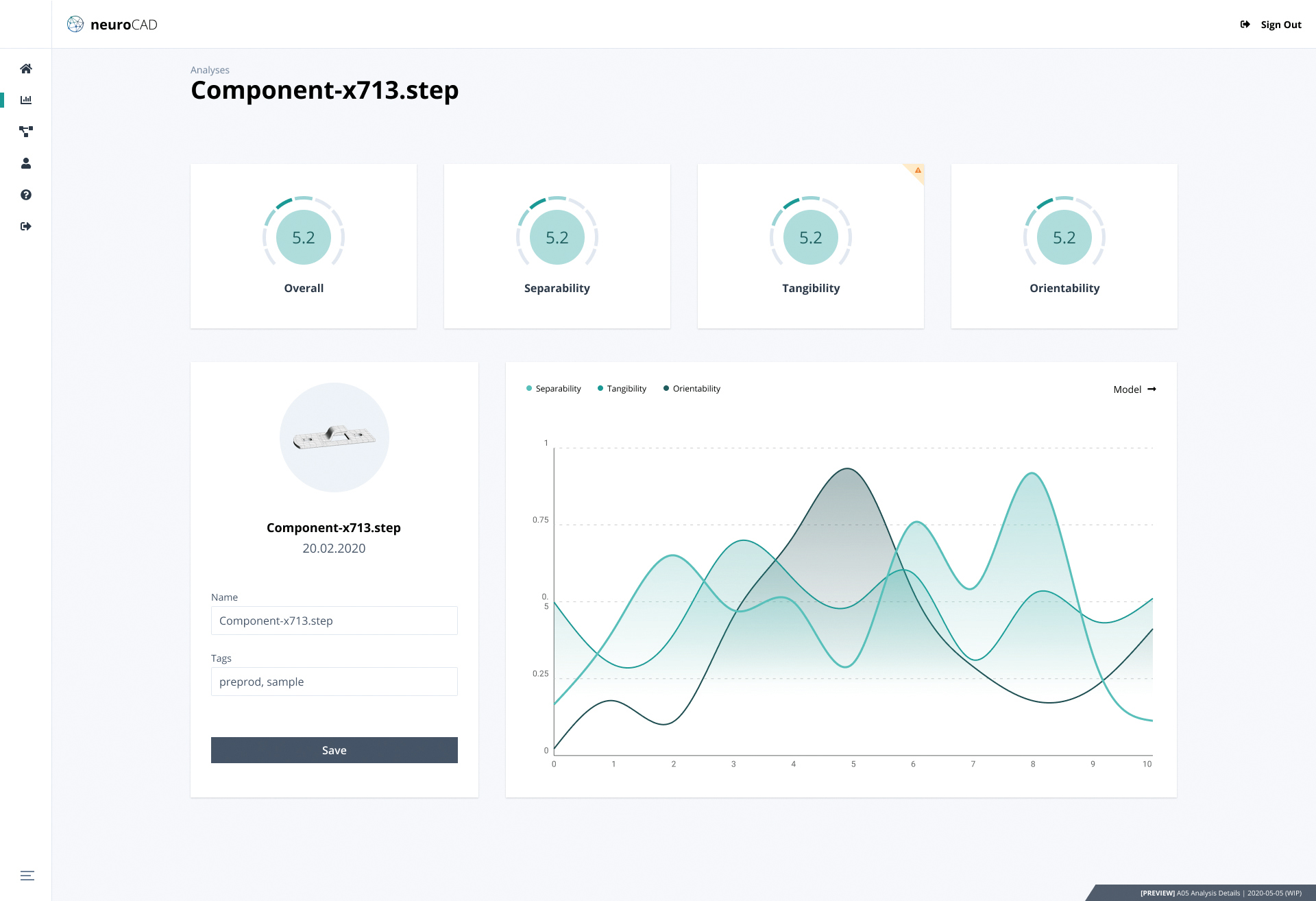

If the app concludes that an assembly process cannot be automated well, it provides the reasons for this. “For example, if there are entanglements or undercuts, crucial sub-processes, such as automated separation or gripping, can become too technically complex or uneconomical,” says Raoul Schönhof, developer of NeuroCAD website and software. While the APA app analyzes existing production, NeuroCAD can be used in the planning process.

The following also applies to the planning phase: Understanding component separability and other criteria that are important to automated production have so far been linked to experts’ experience. Now the software supports NeuroCAD. This automates the assessment using machine learning (ML) processes. In this case, it uses an already comprehensively trained neural network.

Users can access the existing prototype website www.neurocad.de They then have a 3D voxel file of the component within a few seconds, as well as a classification on a 1-10 scale of how easy a component can be separated. “The tool also evaluates the gripping surfaces and alignability of the component,” adds Schönhof. “In the future, a color heat map will show which component properties were important to the assessment. We are currently working on the ability to output further information, such as positionability.” In addition to evaluating components, neural networks also give a probability that their evaluations are correct.

Bring NeuroCAD to practice

NeuroCAD is just one of many examples of how machine learning (ML) methods can help in practical situations today. As part of several publicly-funded projects, the Fraunhofer IPA supports the use of NeuroCAD as well as many other tools for robotics, quality assurance, image processing and optimized production processes.

The software developers have two user groups in mind for whom the tool should prove worthwhile: Product designers can know precisely whether the intended design is suitable for automated assembly even during the planning process for a product. For providers of separation systems, NeuroCAD is a tool with which they can create internal offers, or which can be used externally for sales. In the latter case, customers can upload their step file, state the number of parts they wish to be produced and the delivery date, and the price would be displayed online.

Your expert contact

Katharina Barbu

Vice Head of the research team for automation planning

Phone: +49 711 970-1466